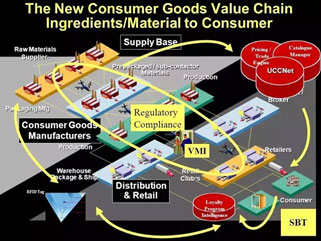

The above visual shows the complexity involved in managing a collaborative Supply Chain.

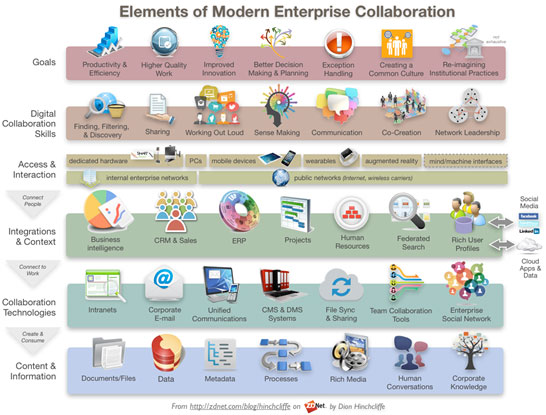

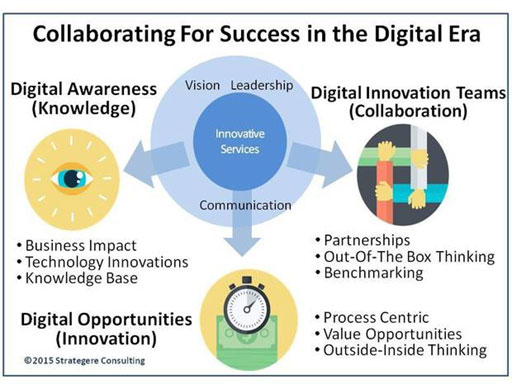

Collaboration today is severely limited without the correct digital tools that allow for vision, implementation, strategizing, flexibility and change.

Steps to building a successful collaborative model.

Priority 1 – get close to your customers

- Find out what is important to them, why they buy from you, and how can you make it easier for them to grow their business with you.

Priority 2 – get close to your vendors

- Same as above except for the vendor side. Understand why you are buying from them, how can you make doing business with them easier, how can you grow your foot print and level of importance for your shared success.

Priority 3 - Build your supply chain based on the information gathered from your customers and partners. Build innovation teams and include your supply chain partners. Start small and work your way up.

Priority 4 – build flexibility into your processes to reflect customer/vendor preference changes as quickly as possible across your supply chain.

Priority 5 – be creative and forward thinking – reimagine your supply chain on a regular basis and keep asking yourself – “Just Imagine if…” (apply no limits on a first pass and then re-invent on following passes).

Priority 6 – continuous reiterative process beginning back with priority 1 and following through repeatedly

Priority 7– never ending process with resulting specific task completions dates after each review as part of the overall process that include your vendors and customers. This is not only an internal project!

Are you equipped to perform the above? Do you have the tools? Do you have the right employees? Do you have the right customers? Do you have the right vendors? Are you listening to your supply chain partners at all levels?

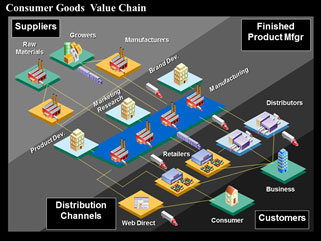

The above graphics are an accurate representation of typical CPG Supply Chains focusing on different daily functions performed in an active supply chain environment.

How can you manage all these fast-moving parts, none of which can be accurately predicted, over a pre-determined time period? The only standard in any supply chain as complex as those applicable to the CPG industry is change! So how do you manage this constant change and provide the services your partners expect?

How do you execute on the 7 priorities listed above for true collaboration and still manage your business?