Inventory Movement using Advance Warehouse in Dynamics 365

Introduction

Location directives in Warehouse Management are user-defined rules that help identify pick and put locations for inventory movement. For example, in a sales order transaction, a location directive determines from where the items are to be picked and where they should be placed.

You can use location directives to do the following:

- Put away incoming items.

- Pick and stage items for outbound transactions

- Pick and put raw materials for production

- Replenish locations

D365 has some built-in strategies for purchase put, sale pick and replenishment pick. Using these strategies, Warehouse and stock management can be carried out effectively.

For Purchase Put, we have to Consolidate and Empty location with no incoming work. Consolidate strategy helps in using the storage effectively and reduce the work time at the time of picking for outbound operation. This strategy checks for the item availability in warehouse locations and assigns the same location for the work.

Empty location with no incoming work helps to avoid having same put location for two different works. This strategy helps by not assigning the location for any other work until the pending work is completed.

For Sale Pick, we have Match Packing Quantity and FEFO Batch reservation. Match Packing Quantity helps in having minimal pick work item rather than having many Pick work items. This helps in reducing the time consumption to do a work by avoiding picking of items from different locations for a certain order. It checks the shipment quantity with the location quantities and if it is sufficient to fulfill the requirement, system will assign that location as a pick location for that work.

FEFO batch Reservation helps in Sell/Use the item which has an earlier expiry date.

For Replenishment Pick, we have roundedup a Full LP and Round up a Full LP with FEFO Batch Reservation. Replenishment work is created when there is a shortage of stock in location to fulfill the sales requirement. To avoid repeated replenishment work in future, this strategy can be used so that work is created to shift the entire LP quantity. from Bulk location to Pick Location.

Prerequisite:

Basic Knowledge about below topic helps in understanding the blog better

- Purchase order

- Sale order

- Warehouse Operation

- Location Directive

- Work template

Location Directive Strategy:

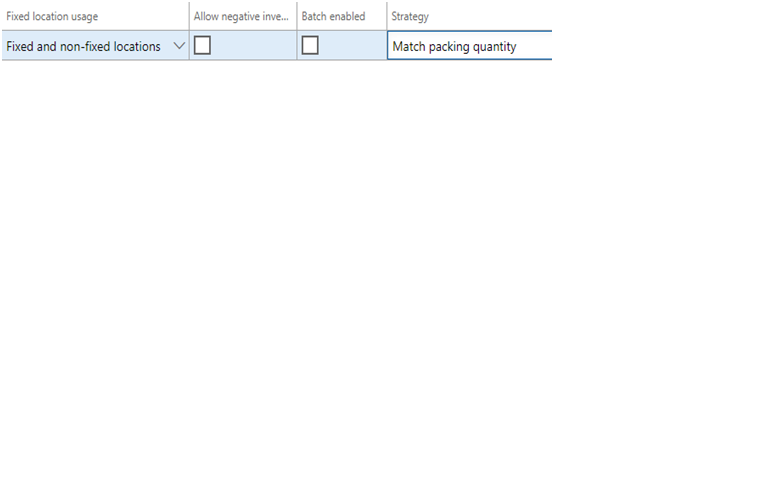

In D365, we have some strategies based on which location for Pick and Put location is defined for a work. Strategy should be defined under “Location Directive Actions”.

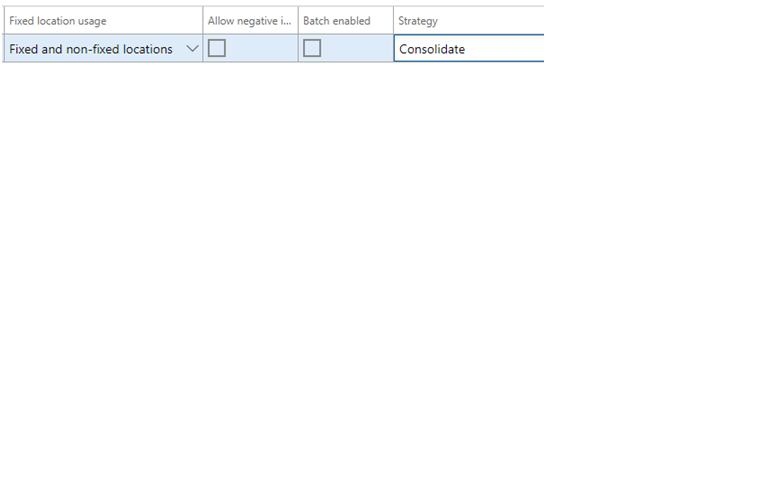

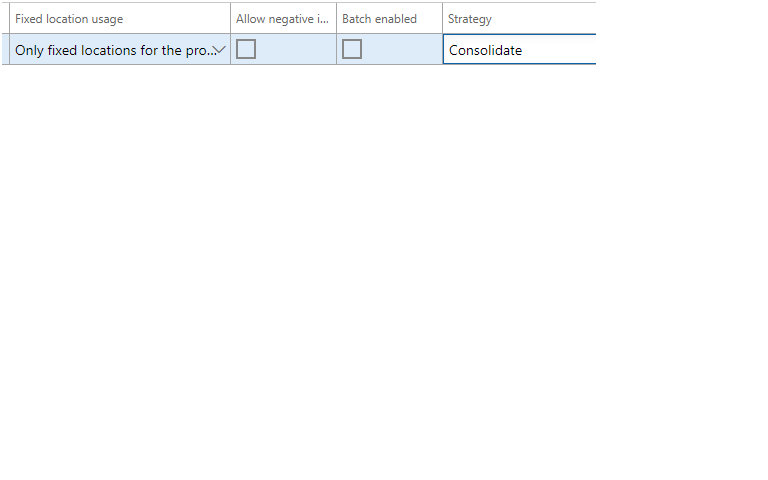

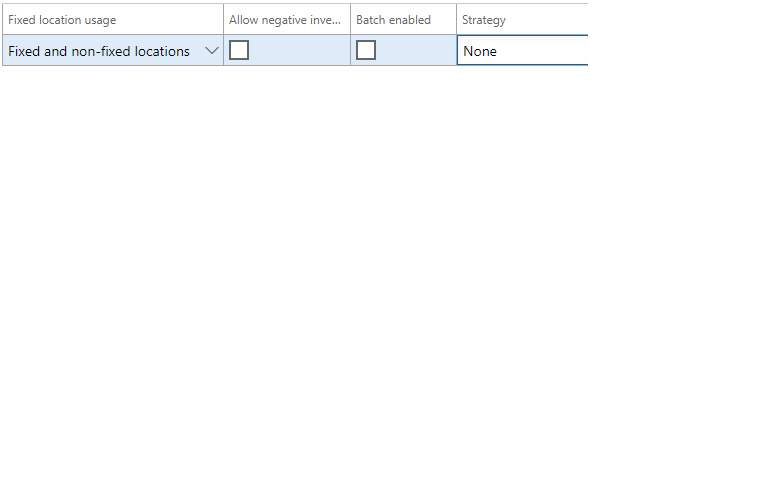

When Fixed Location Usage been selected as “Fixed and Non-fixed Location” then D365 will check all locations which meet the criteria in edit Query else it checks only fixed location which meets the criteria.

Let us now understand how this works in the below scenario

Fixed location can be defined under Warehouse management -> Setup -> Warehouse -> Fixed Locations

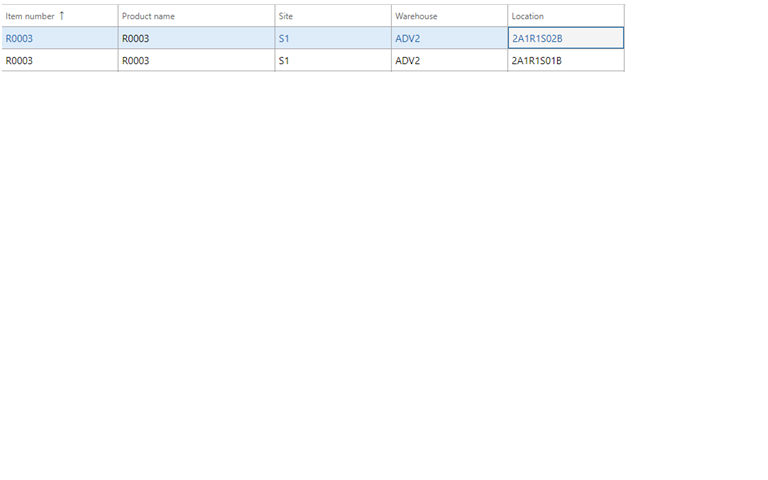

- Fixed location has been defined for the Item R0003.

- In-stock of the item R0003

- When Strategy is None, D365 defines the put location by sorting the location in ascending order which meets the criteria in edit query.

- Since Location is in alpha-nuumeric column when sorting in ascending order, the order will be in the order: special character, Numeric and then alphabet.

Purchase Put:

Under Purchase Put the only strategy that can be used is:

- Consolidate

- Empty location with no incoming work

- Consolidate

Fixed and Non Fixed Location

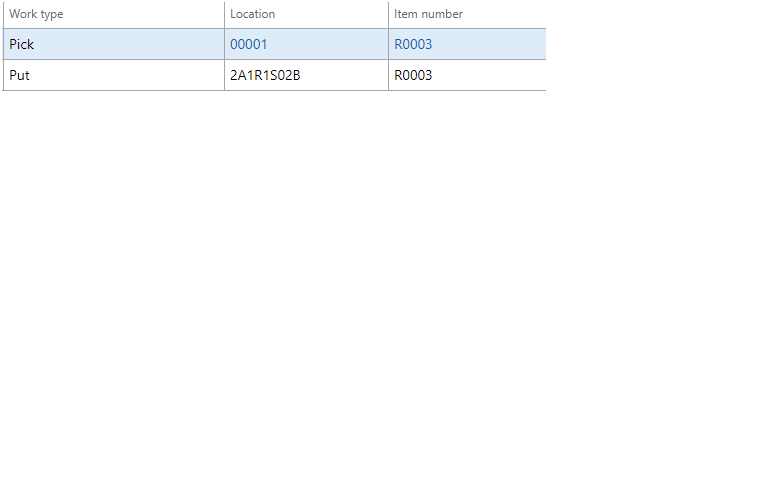

- When strategy is changed to consolidate, D365 checks which location has the same item already and defines the same location as Put Location.

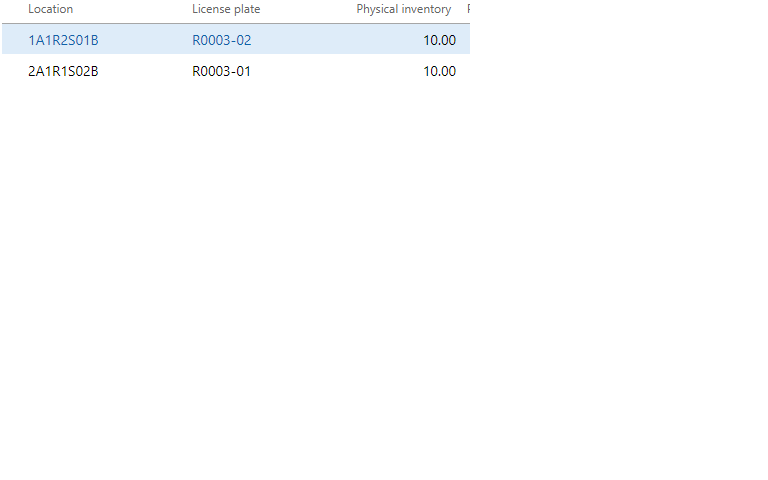

- Item R0003has in-stock of

- 10 quantity. in “1A1R2S01B” and 10 quantity. in “2A1R1S02B”

- Fixed location is “2A1R1S01B”,“2A1R1S02B”

Location Directive

Work Line

Fixed Location

Location Directive

Work Details

- Empty location with no incoming Work

- When this strategy is being used, D365 defines the location ‘Empty location’ physically and ‘no Put work’ gets assigned to the location.

Sale – Pick

- Match packing quantity

- This Strategy checks whether a pick location has the specified packing/Shipment quantity. If there is no LP matching the packing/shipment quantity., then system checks next line under “location directive Action”.

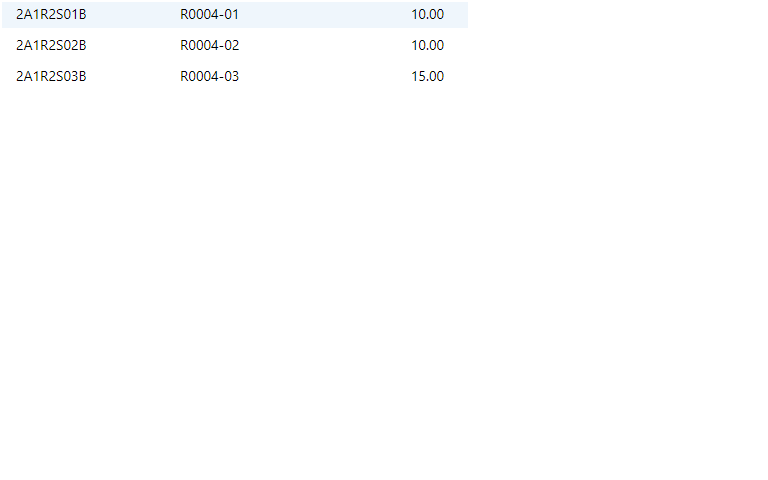

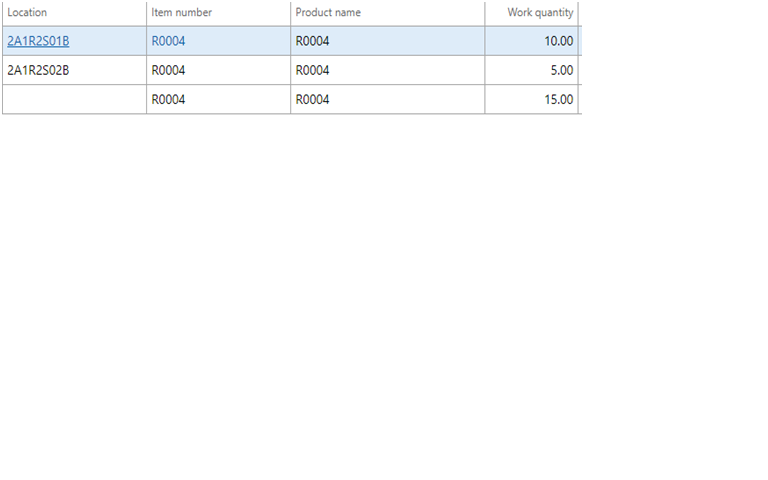

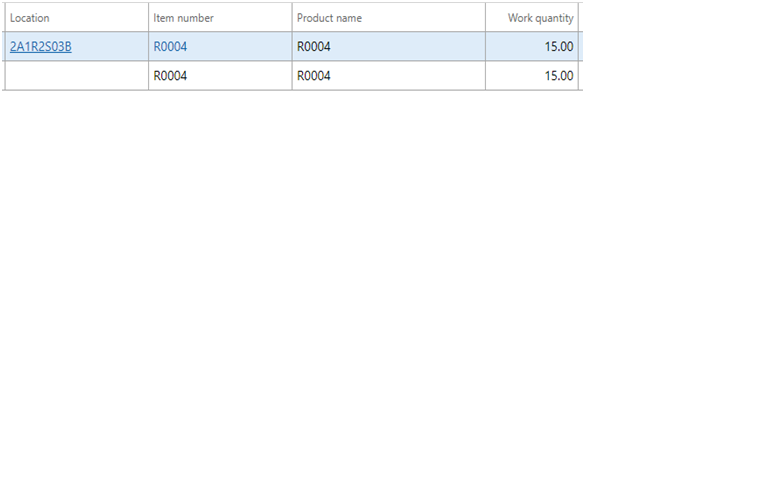

- Item R0004 has 35 has in-stock in 3 different location as below

- We have a sale order for 15 quantity.

Location Directive - Pick

- When strategy is “None”, D365 defines the location when in stock is greater than 0 and orders the location in ascending order.

- When Strategy is “Match Packing Quantity”, D365 checks the location where any LP matches the Shipment quantity.

- Since location “2A1R2S03B” has a LP with 15 quantity., D365 define this field has Pick location for the shipment.

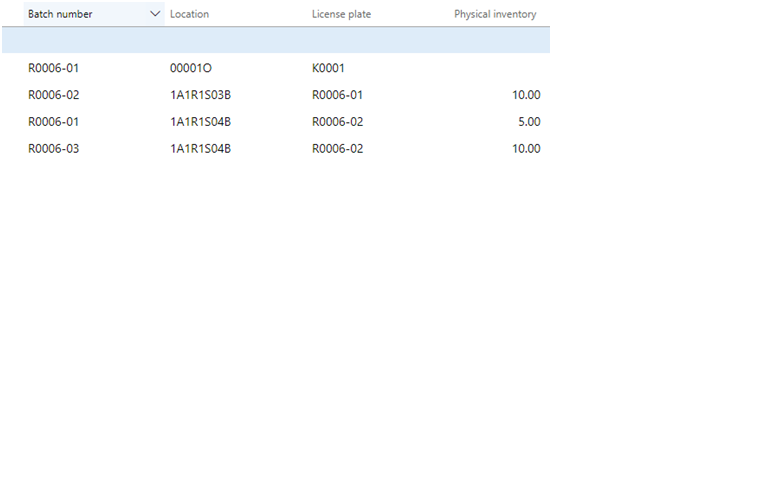

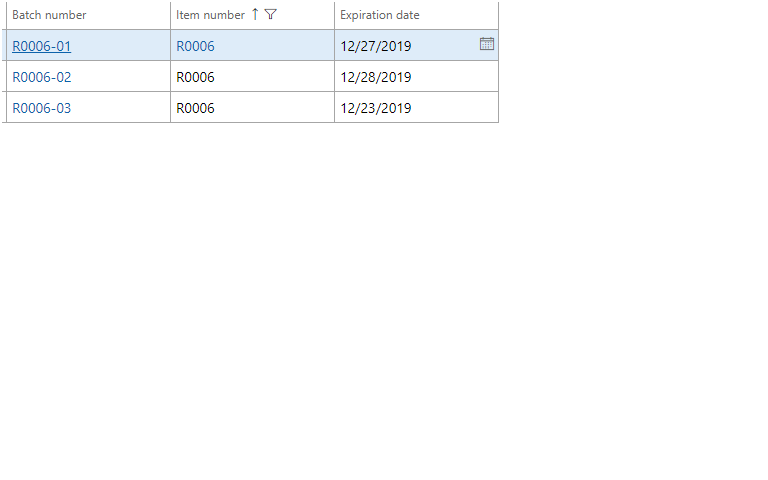

- FEFO batch Reservation

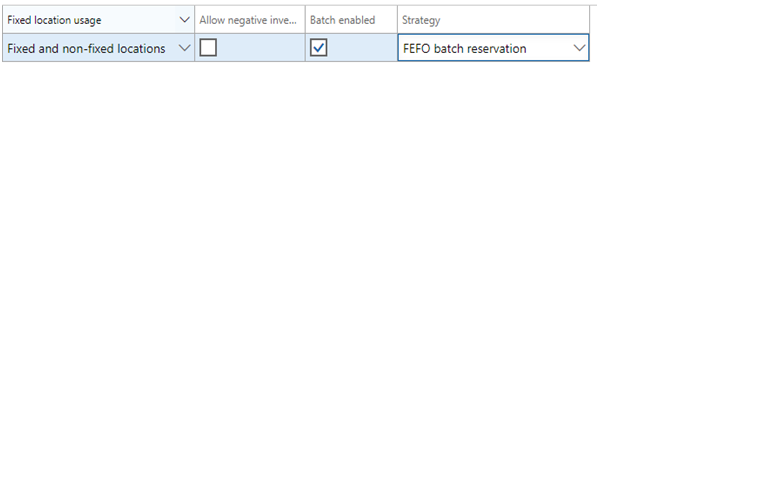

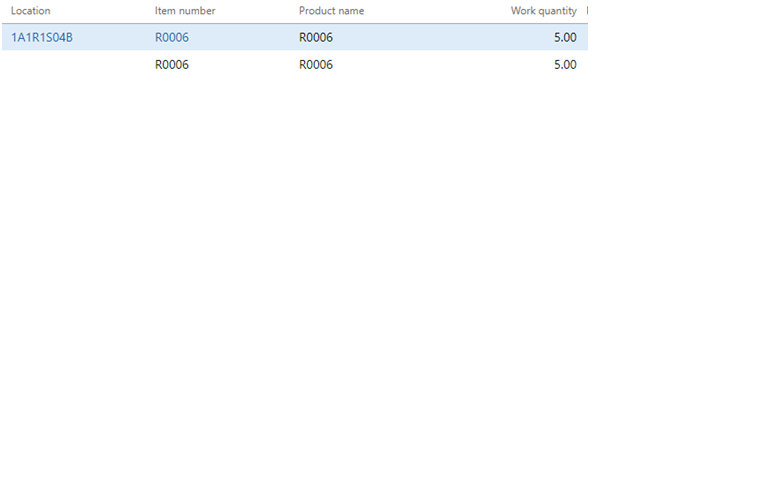

- This strategy checks the location directive and defines the pick location if there is any batch available with an earlier expiry date.

- “FEFO Date-Controlled” under Item model group needs to be enabled.

- Reservation Hierarchy should have batch below location.

- Item “R0006” has 25 stock in direct location.

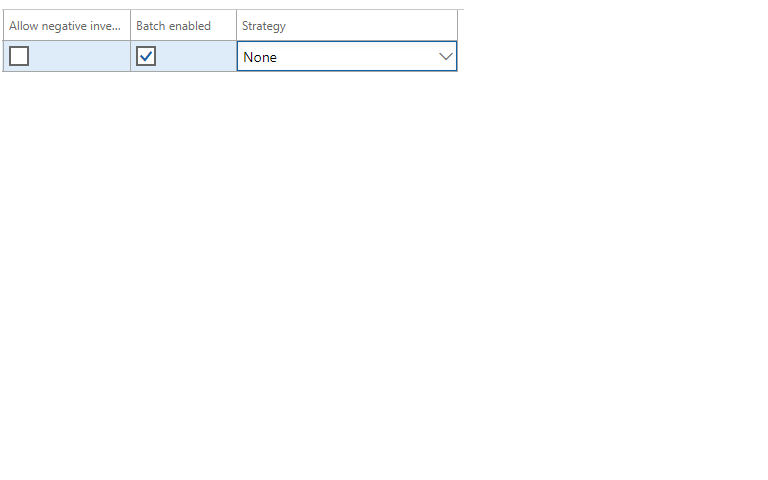

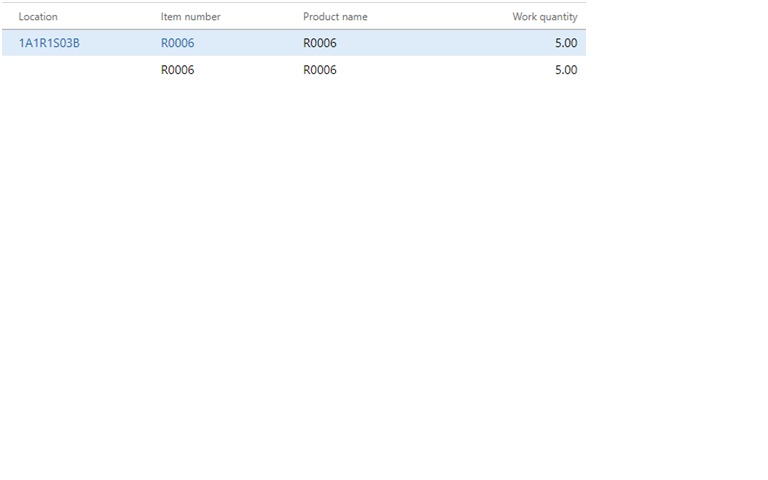

- When Strategy is “None”, D365 defines the first location which has stock.

Work Line

- When Strategy is “FEFO batch reservation”, then D365 suggests the location in which earlier expiry date batch is available.

Location Directive

Work Line

Replenishment – Pick

- Round up to full LP

- This Strategy is used to round up the inventory quantity to match the license plate (LP) quantity that is assigned to the items to be picked.

- When a replenishment wave is created, work will be generated for the entire LP available in bulk locationwith no break of quantity.

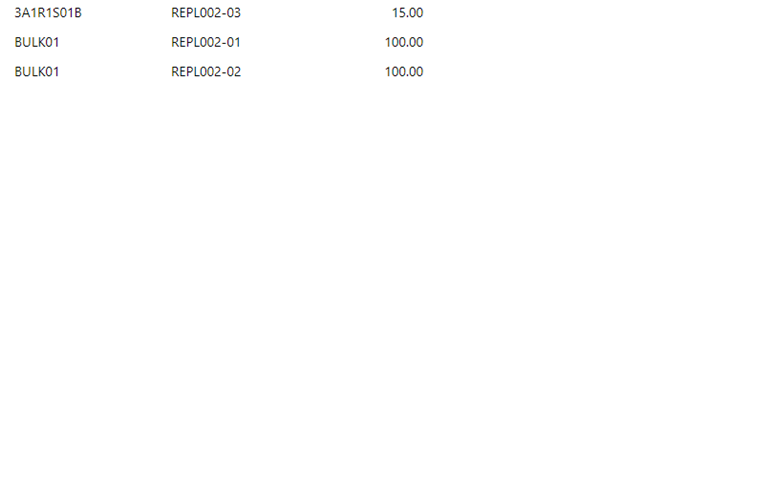

- Sale order for item REP002 – 25 quantity.

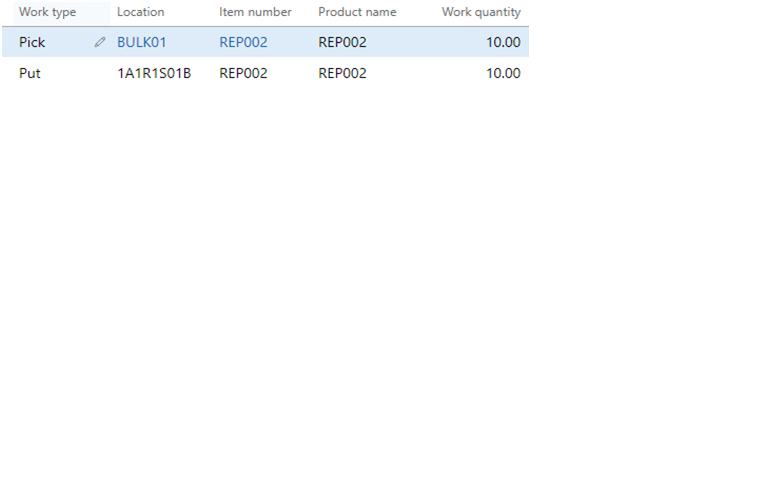

- When using replenishment in Wave, the system creates separate Work for shift stock from bulk location to picking location.

- Since we have 15 in pick location, D365 creates a work for 10 quantity. from Bulk01 to 1A1R1S01B.

- And another order for Sale pick as below

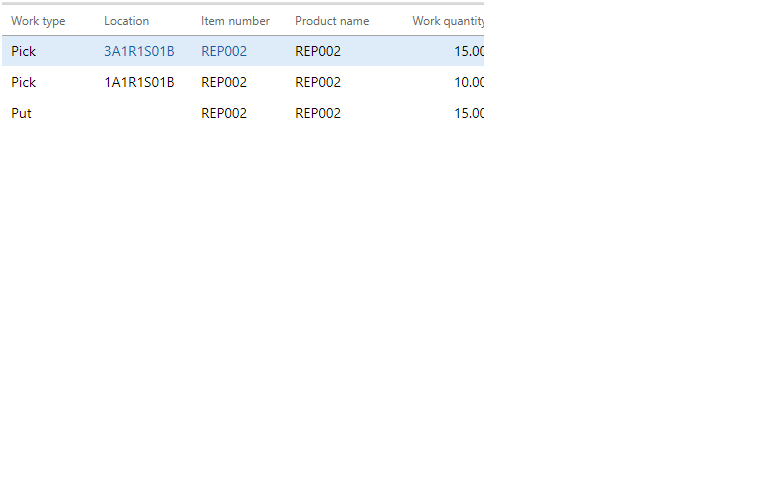

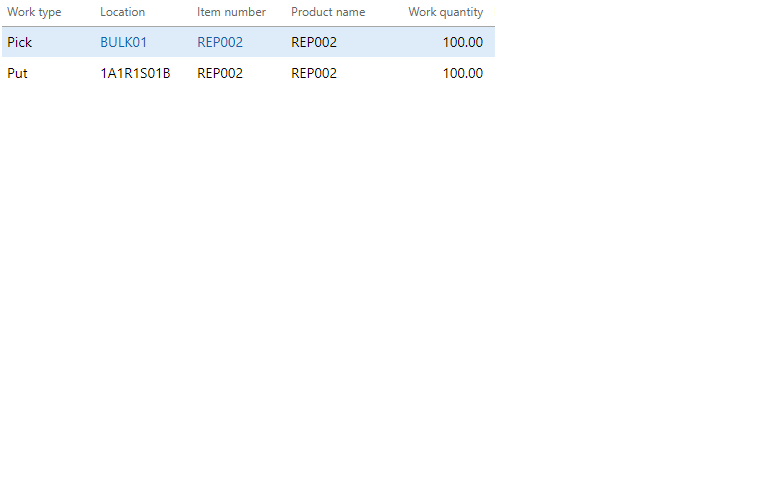

- When strategy is changed to “Round up to full LP”. D365 checksthe available LP in bulk location which has sufficient quantity to fulfill the need and does not break the LP. Entire LP quantity. will be moved.

- LP quantity. is selected based on FIFO methodology by default.

- If there are two LPs with 70 quantity. in one LP and 30 quantity. in another LP. System will select LP which is in-warded first.

- If 70qty. is in-warded first then work quantity. for replenishment will be 70. If 30qty. is in-warded first then work quantity. for replenishment will be 30.

- Replenishment Work

- Sale order Work

- Round up to full LP and FEFO batch

- Round up to full LP and FEFO batch is similar to the Round up to full LP when generating Replenishment work, D365 checks the LP which is of the earlier Expiry date batch. It can be used only for replenishment.

- License plate guided

- License plate guided is used in cross dock